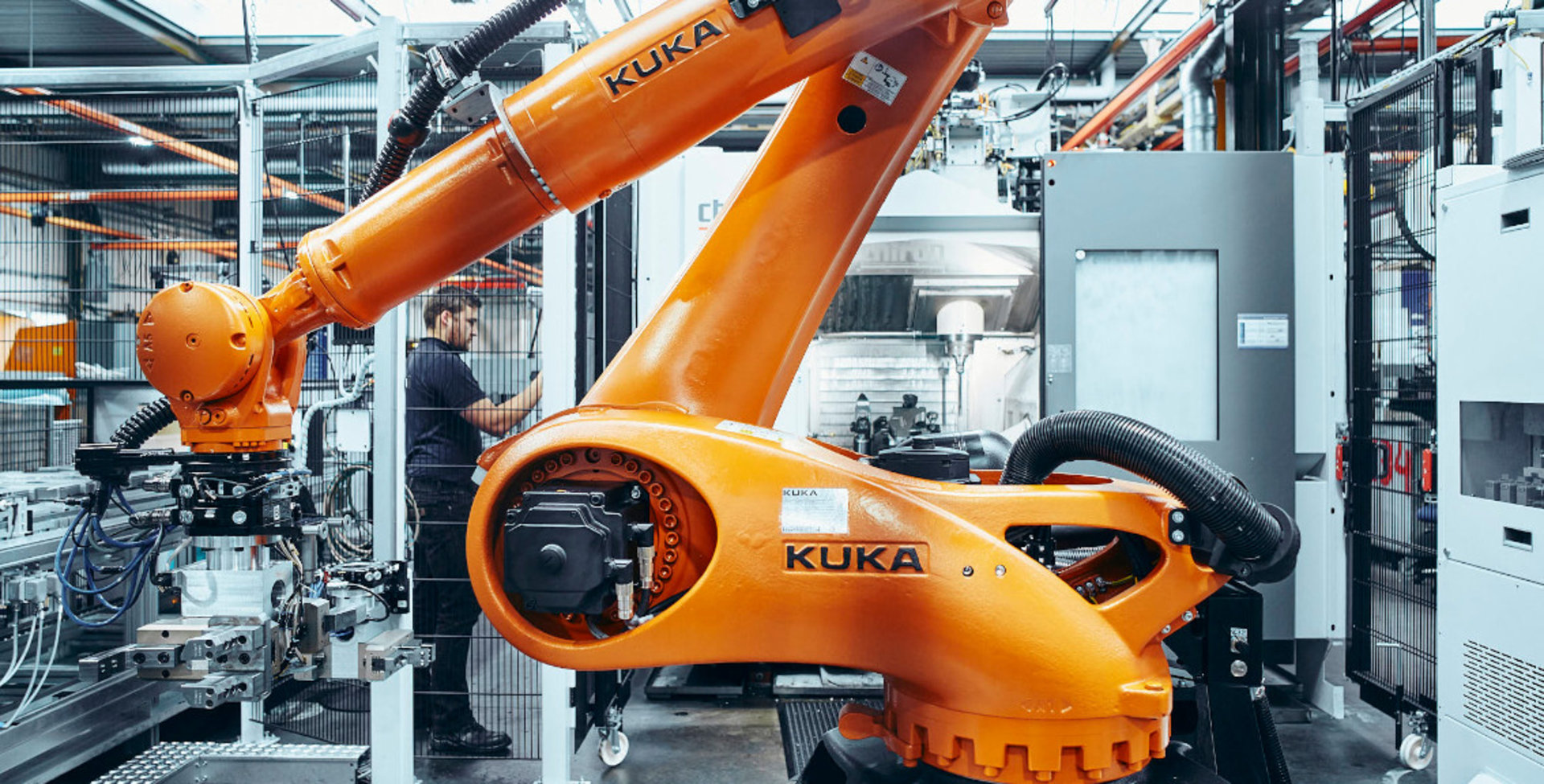

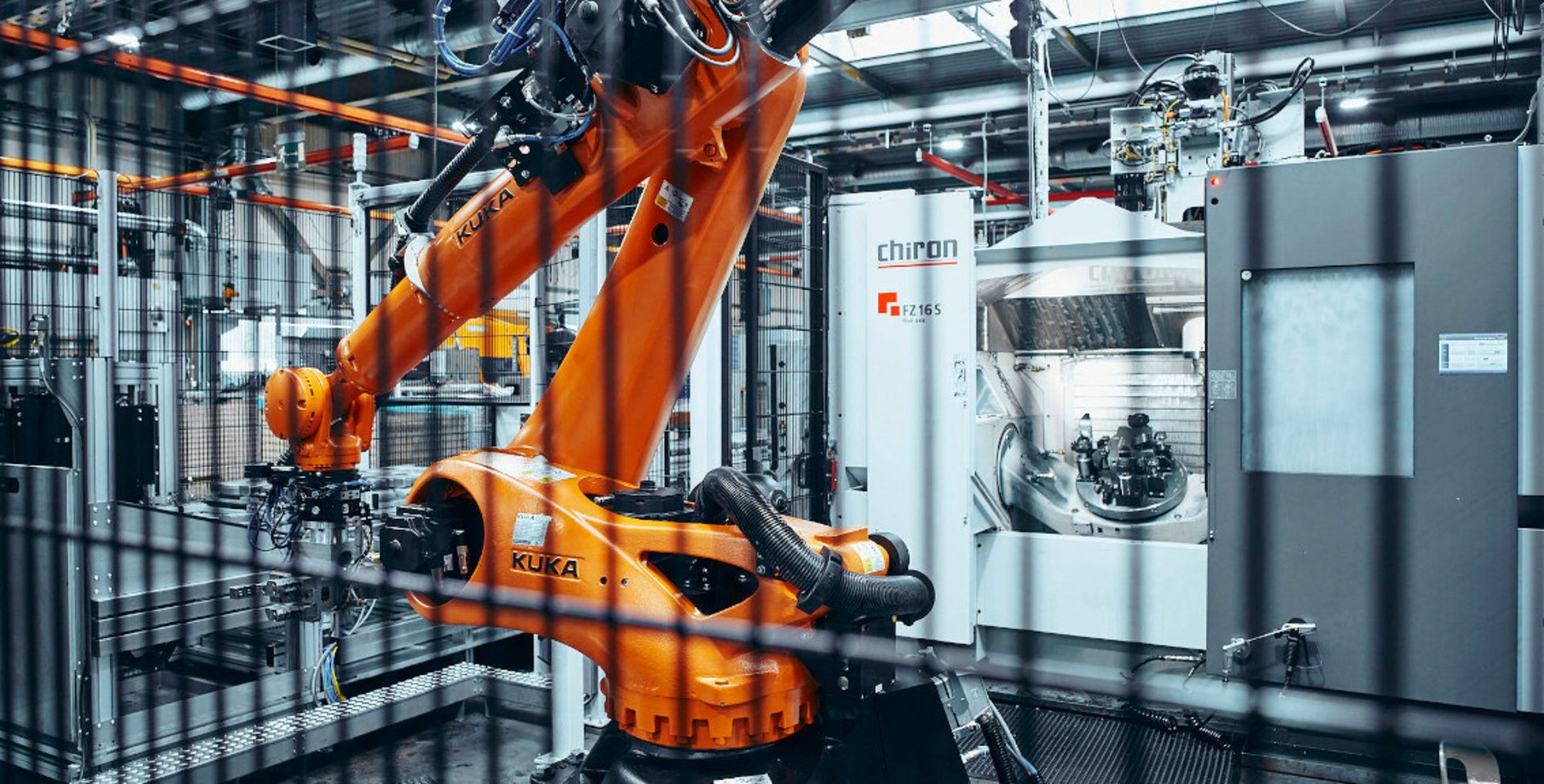

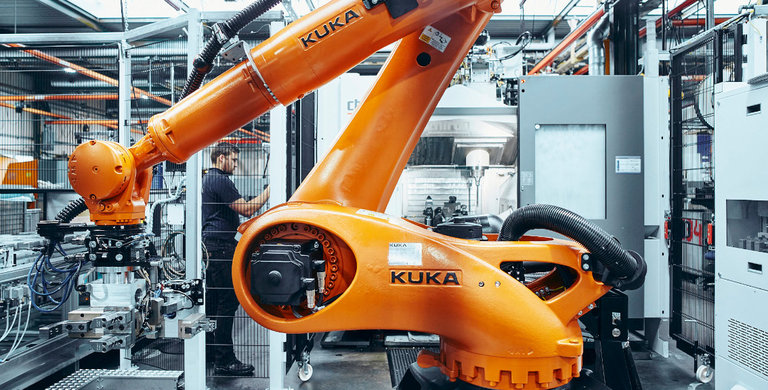

TECHNOLOGIE OBRÁBĚNÍ

Spokojenost zákazníků = faktor úspěchu

Jsme dobře vybaveni pro nejběžnější obráběcí procesy. Naše téměř 40-leté zkušenosti a know-how jsou optimálním základem pro dokonalé zpracování všech kovových materiálů dle konkrétních požadavků zákazníka.

Máme volné kapacity obrábění!

MÁTE ZÁJEM?

Napište nám nezávazně.

Těšíme se na Vaše poptávky:

Těšíme se na Vaše poptávky:

NAŠE NABÍDKA

Vlastní obrábění

| Frézování | až do 5 os, 850 mm x 960 mm x 700 mm |

| Obrábění | průměr 50 – 550 mm, maximální délka 1.000 mm |

| Broušení | vnější průměr do 300 mm |

| Vyřezání ozubení | max. 6 modulů, drážkované nebo frézované |

Externí služby

| Tepelné zpracování a povrchové úpravy | Povrchové kalení, všechny nitridační procesy, temperování, tvrdé chromování, fosfátování manganem, indukční kalení, žíhání, leštění, niklování, základní barva, práškové lakování, katodové lakování |

| Doplňkové mechanické metody | Pilování, protahování ozubených kol, vyvažování |

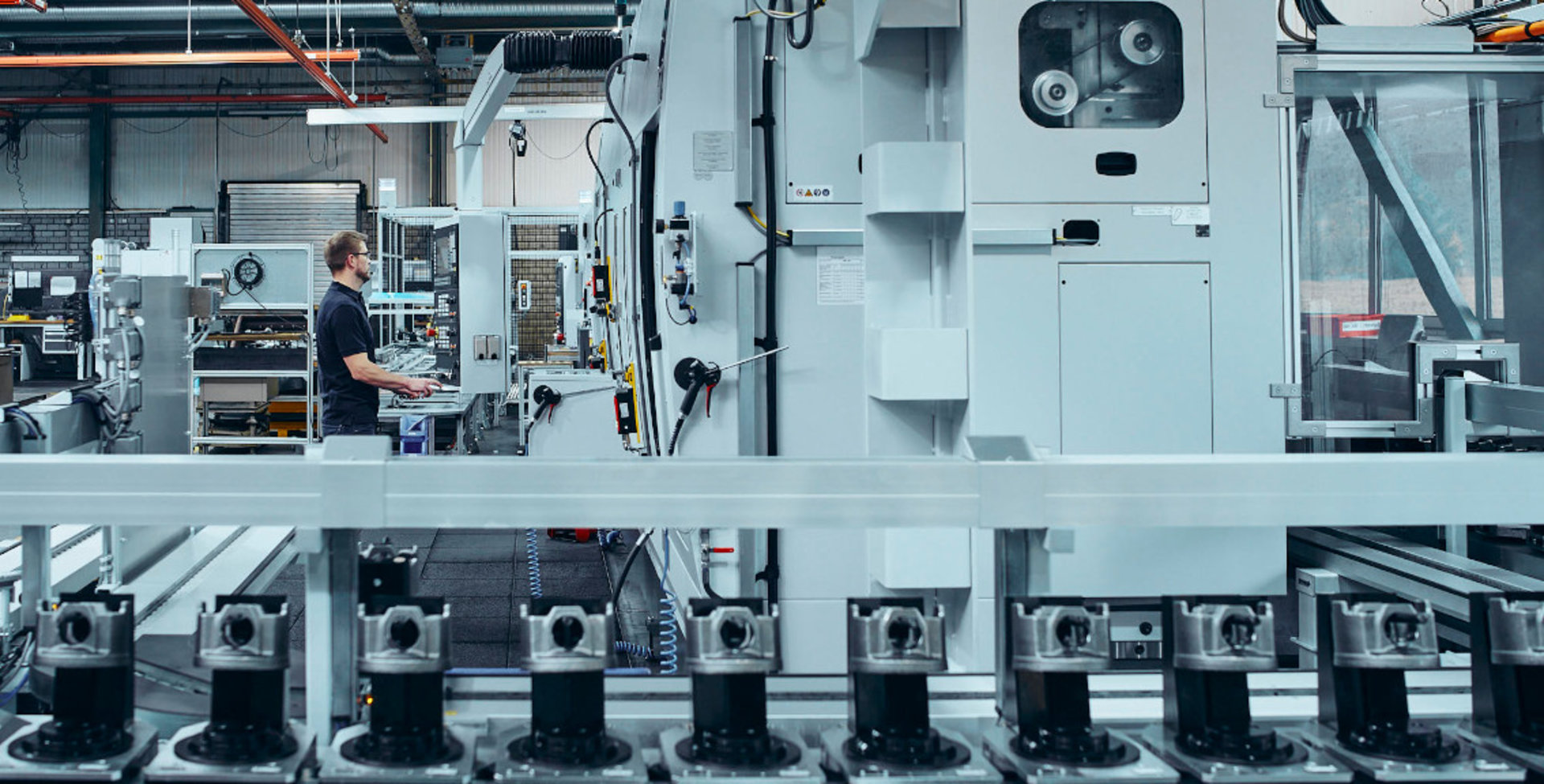

CÍLOVÉ OBROBKY

| Rozměry | Hranoly: 400 mm x 400 mm x 400 mm Rotačně symetrické: průměr 50 mm až 550 mm, max. délka 1.000 mm |

| Minimální dávka | 150 kusů (max. roční množství cca. 50.000 ks) |

| Materiály | Ocel, nerezové oceli (hliník, litina, neželezné kovy) |

| Hmotnost dílu | 2 – 45 kg |

Naše zaměření

V našich závodech ve Fridingenu a Chebu máme široký strojní park, jak pro obrábění Vašich výkovků z oceli, tak pro další konvenční obrábění např. neželezných kovů.

Máme volné kapacity obrábění!

MÁTE ZÁJEM?

Napište nám nezávazně.

Těšíme se na Vaše poptávky:

Těšíme se na Vaše poptávky: